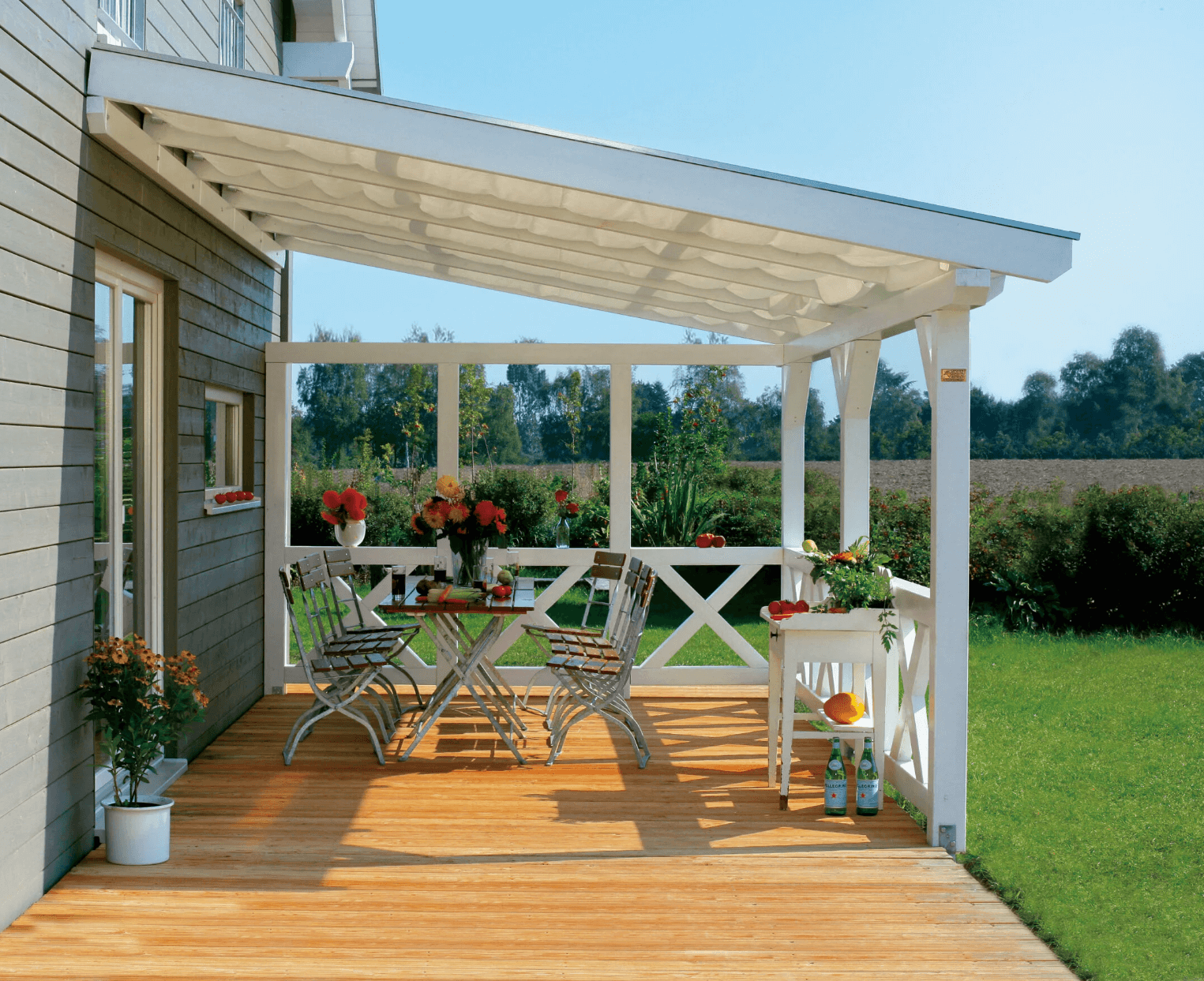

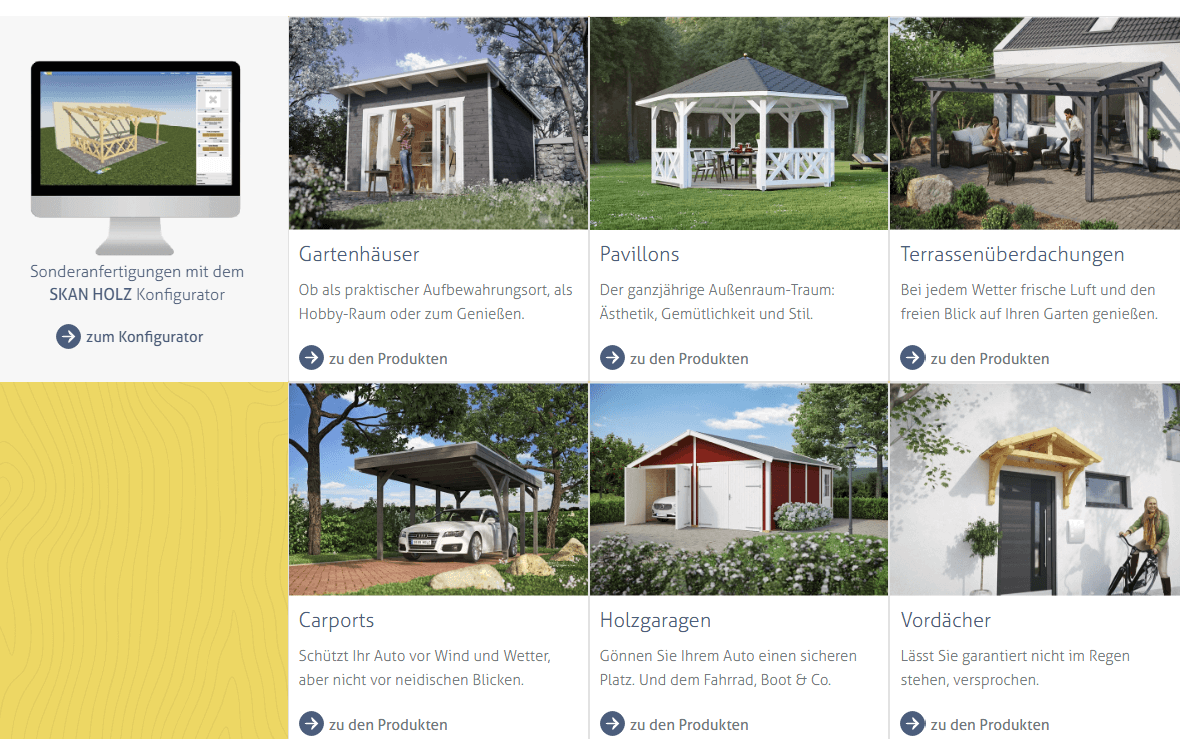

SKAN HOLZ Europe GmbH is a German manufacturer of prefabricated wooden structures, including garden houses, carports, pavilions, and other outdoor buildings. Founded in 1979 and based in Bendestorf, the company serves the European market through online sales, B2B wholesale, and export channels.

Its products are modular, highly customizable, and made from wood and aluminum to meet diverse customer needs. An online configurator enables customers to design and personalize their structures, while the company efficiently manages complex product variants and multilingual content across multiple markets. Skan Holz places strong emphasis on quality craftsmanship, durability, and sustainability in all of its offerings.

Building a Scalable PIM Ecosystem for a Leading Timber Construction Manufacturer

Challenges

Skan Holz faced several key challenges in managing and optimizing its expanding product data ecosystem:

Outdated PIM Software: The legacy PIM lacked modern features and scalability. It received infrequent updates and could no longer meet growing data and process requirements.

Complex Data Integration: The new Shopware-based online catalog required full product data synchronization. Connecting the PIM and Shopware was technically challenging.

Manual Multilingual Management: Managing translations across 11 European languages was slow and error-prone. The process lacked automation and caused inconsistencies in product content.

Manual Assembly Instruction Creation: Assembly instructions had to be created manually for each product and variant. Synchronizing these materials with Shopware was inefficient and time-consuming.

Manual Product Data Sheet Creation: There was no automated way to generate or update product data sheets. Synchronization with the online catalog required repeated manual effort.

Goals

To address these challenges, Skan Holz set out to:

Implement a Modern PIM System: Deploy a high-performance PIM that supports complex product data, technical specifications, and multilingual content with full scalability for future growth.

Enable Bulk Editing and Imports: Allow teams to update product descriptions, attributes, and variants across thousands of SKUs efficiently through mass updates and imports.

Automate Data Synchronization with Shopware: Establish variant-based synchronization between the PIM and the Shopware online catalog to ensure accurate and up-to-date product data.

Automate Data Sheet and Assembly Instruction Creation: Introduce automated generation of data sheets and multilingual assembly instructions using structured templates and reusable content blocks.

Implement Translation Workflows: Centralize translation management with glossaries and translation memory tools to maintain consistent brand tone and terminology across all markets.

Solution

Skan Holz implemented a modern PIM system, AtroPIM, designed for flexibility, scalability, multilingual support, and secure data management.

Key features included:

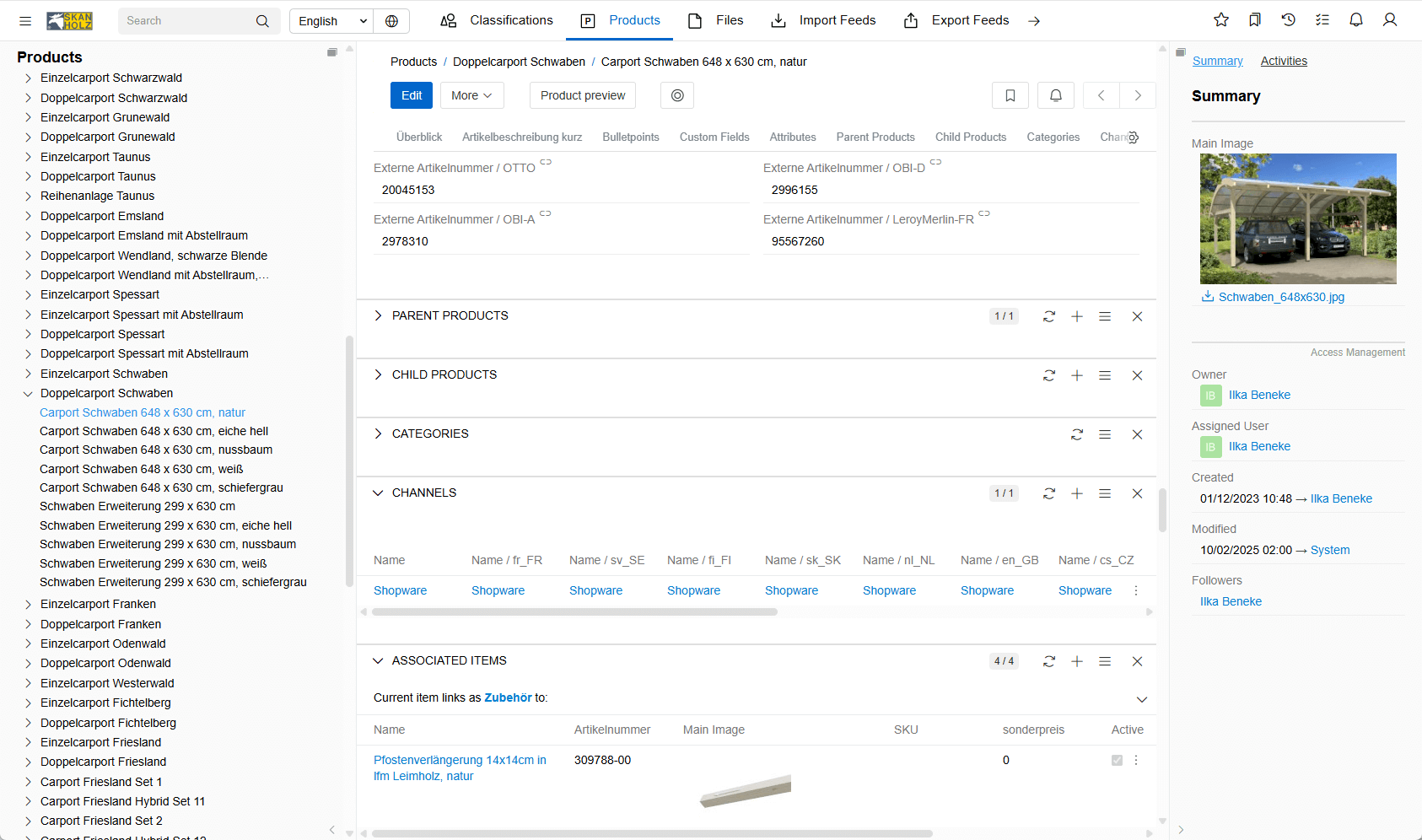

Central Hub: AtroPIM consolidates all product information and media files, providing a single source of truth with full flexibility and security.

Data Migration: Legacy PIM data was normalized with custom adapters. Excel files were imported via standard tools to ensure a smooth transition.

Workflow & Collaboration: Teams use a flexible workflow engine to manage product data. Import/export tools enable fast updates across the catalog.

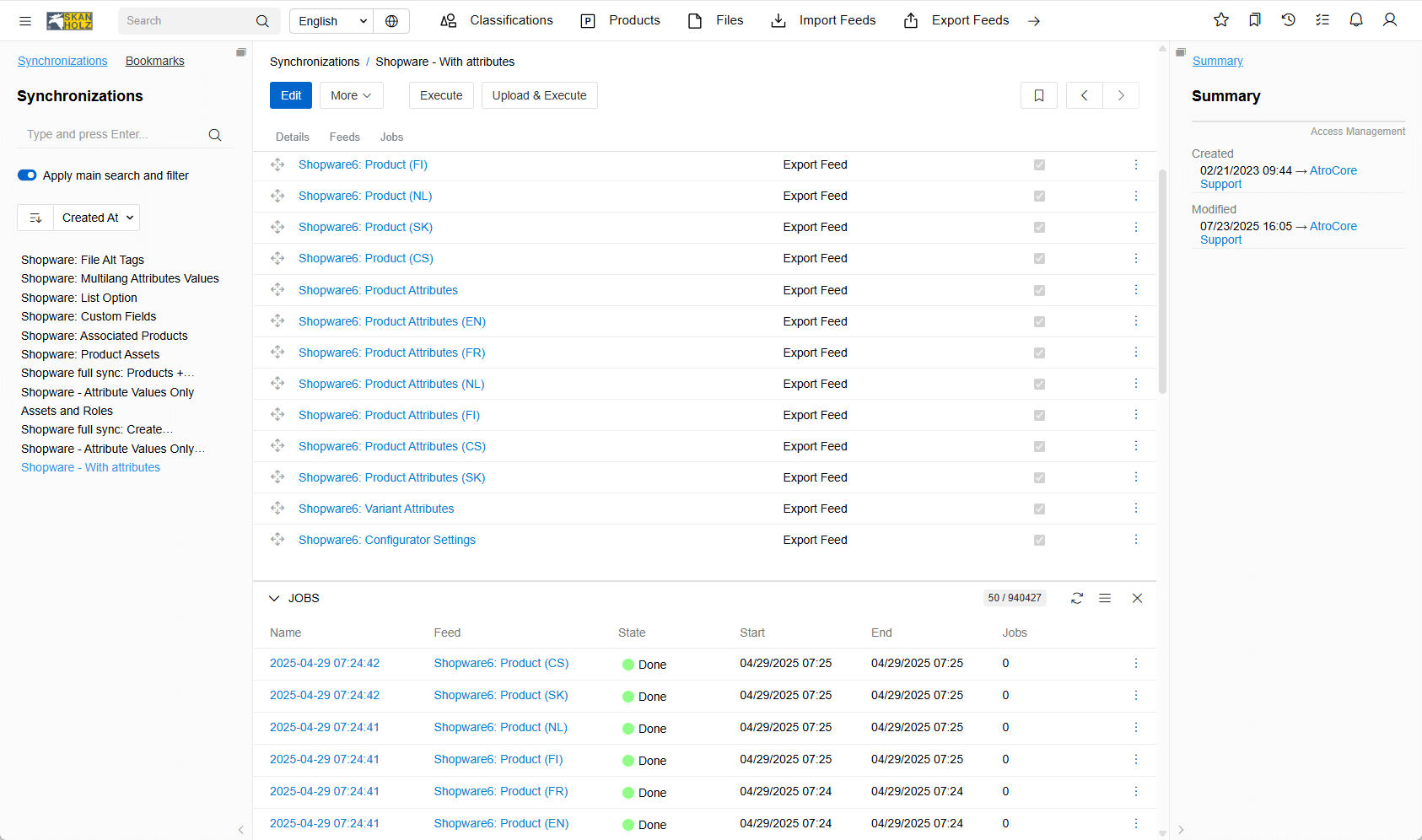

Shopware Synchronization: Product data, including custom fields and media, is synced daily. Only new or updated records are transferred for efficiency.

Automated Document Generation: Datasheets and assembly instructions are generated automatically, translated into 11 languages, and watermarked. Modular blocks allow flexible creation and reuse.

Future-Ready Architecture: The system is scalable and ready for additional integrations and automation.

Results

Centralized Data Platform: All product information is managed in one unified PIM system. The platform serves as the single source of truth in 11 European languages and ensures consistent and accurate data.

Streamlined Product Updates: Bulk import and export tools allow quick updates of product descriptions, attributes, and variants. Teams can manage large-scale changes with minimal manual work.

Automated Translation Workflows: Translation memory and glossaries automatically translate all content from German into ten European languages. The process maintains consistent terminology and brand language.

Automated Data Integration with Shopware: Product data, datasheets, and assembly instructions are synchronized automatically with the Shopware-based catalog. Only new or updated data is transferred to improve efficiency and stability.

Efficient Variant Management: Multi-level hierarchies organize product variants clearly. The structure simplifies maintenance and keeps relationships between variants accurate.

Streamlined Channel Syndication: Product data is automatically prepared and distributed to various sales channels and DIY markets.

Scalable and Future-Ready Architecture: The new PIM system provides a flexible and multilingual foundation. It supports faster updates, better data quality, and ongoing digital growth.