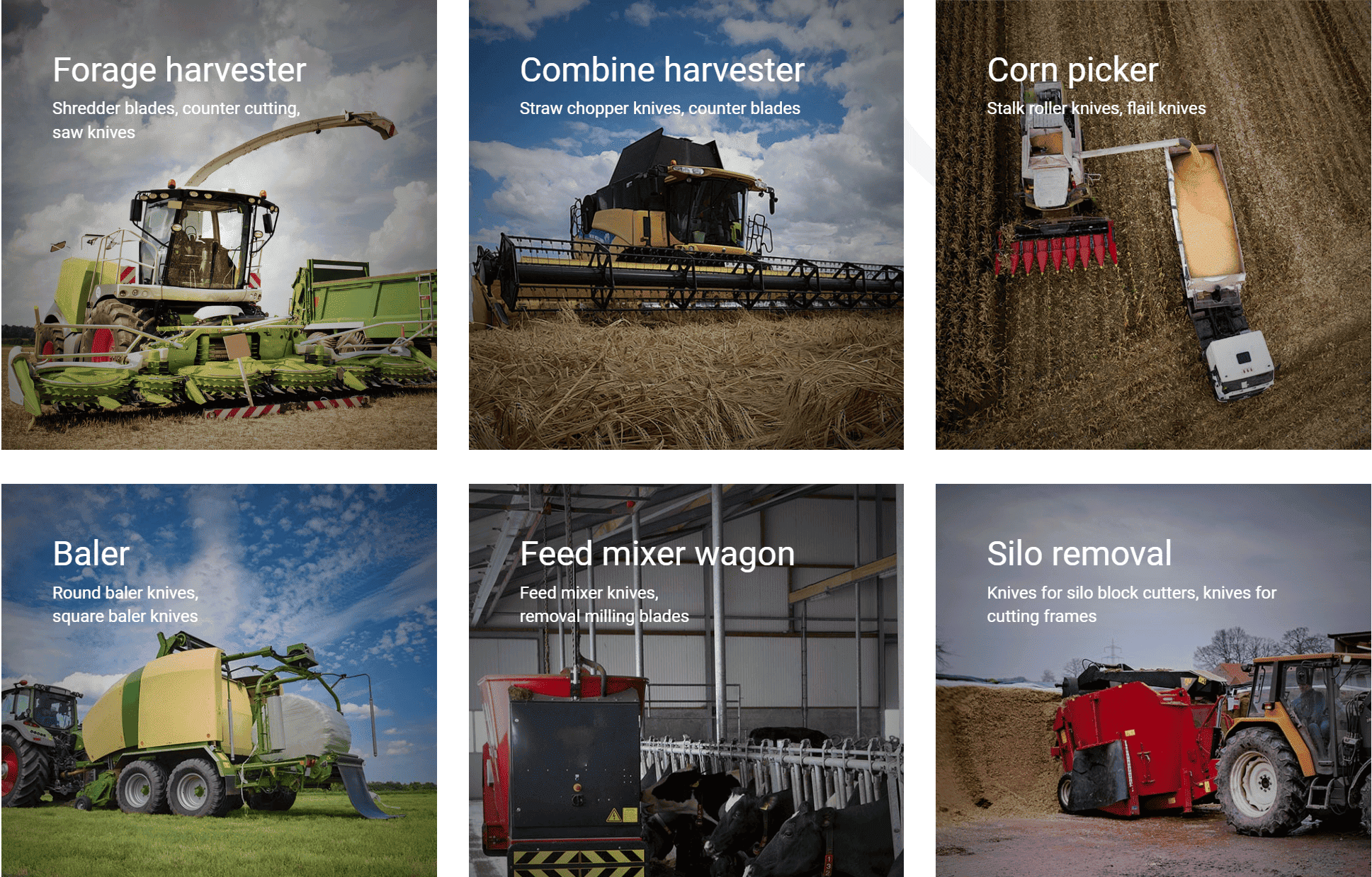

MWS Schneidwerkzeuge GmbH & Co. KG is a German manufacturer of precision cutting tools and industrial blades based in Schmalkalden, Thuringia. The company is part of the Mendritzki Group and specializes in producing knives and blades for applications in agriculture, forestry, municipal technology, tire production, and recycling.

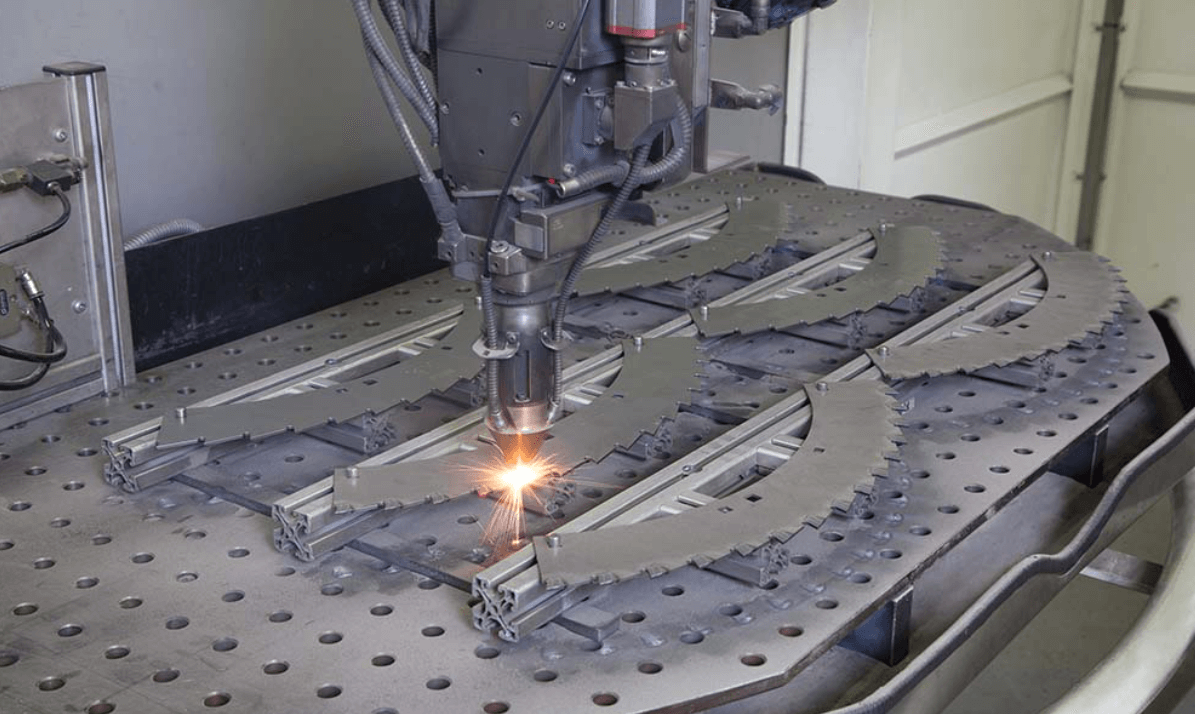

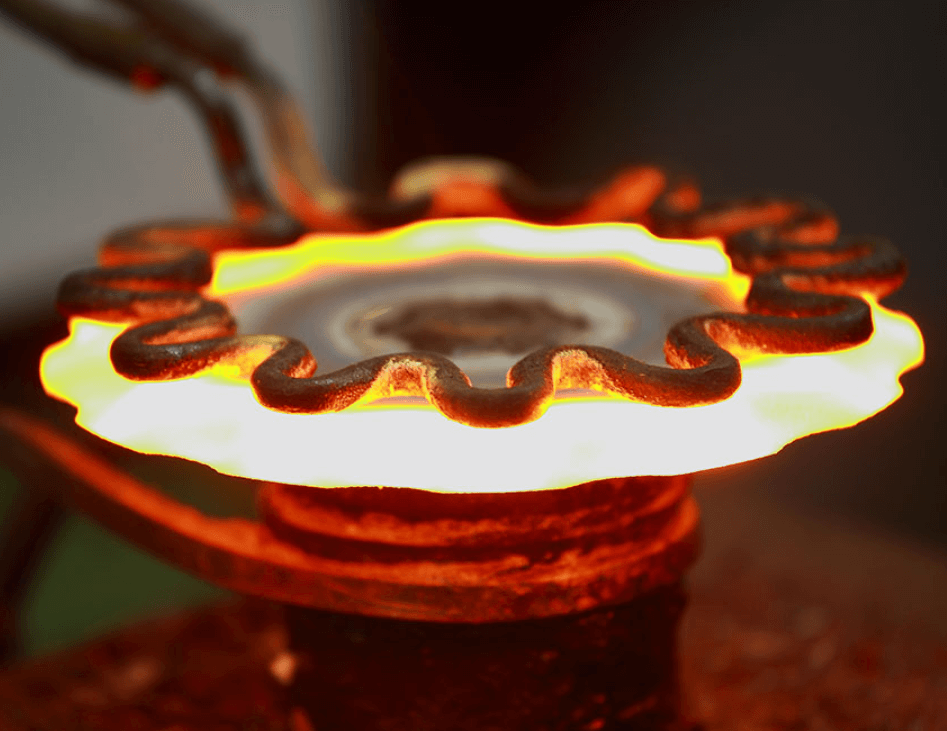

MWS manages the full production process in-house, from steel strip processing to finished components, supported by modern milling, grinding, coating, and heat treatment facilities. The company’s product brands, MWS and MTV, are used worldwide in demanding industrial environments.