First Stop Ayme is a leading French provider of tyre and automotive services, headquartered in Saint-Priest, France. Formed in 2020 through the merger of Métifiot Pneus and Ayme & Fils (both Bridgestone subsidiaries), the company unites several established networks under the First Stop brand.

With nearly 500 service centers across France and the Benelux region, First Stop Ayme offers tyre solutions, vehicle maintenance, and fleet services for a wide range of vehicles, from passenger cars to industrial equipment.The company is supported by 1,500 employees and plays a key role in the automotive aftermarket and mobility sector. Additionally, First Stop Ayme has implemented advanced business intelligence tools to manage its extensive retail network effectively.

Driving Automotive Velocity by Centralizing Product Data Across 500+ Service Centers

Challenges

First Stop faced several key challenges in managing their large and complex automotive product data ecosystem:

Inconsistent Supplier Data: Product information came in different formats from multiple suppliers, often with conflicting details that had to be verified and standardized.

Managing Complex Product Attributes: Products had many types of attributes, some calculated dynamically, requiring an easy-to-use interface for logistics, marketing, and technical teams.

Ensuring Data Quality: Nearly a million SKUs across multiple sources made it difficult to check completeness and accuracy without better validation tools.

Customized Data Exports: Partners required tailored datasets with specific products, attributes, and pricing, needing more efficient and reliable export processes.

Access Control Complexity: Permissions depended on supplier, product category, and manufacturer, making secure and compliant data sharing challenging.

Goals

To address these challenges, First Stop aimed to:

Implement a Central PIM System: Deploy a scalable PIM to centralize product data and make it easier for teams to access and manage.

Automate Data Imports: Regularly synchronize product information from multiple sources without manual work.

Apply Brand and Category Rules: Filter and process products based on source, brand, and category to keep data accurate and relevant.

Automate Product Enrichment: Calculate attributes, categorize products, and update statuses automatically according to rules.

Schedule Product Exports: Set up reliable, channel-specific exports to partners and external systems on a regular basis.

Improve Data Quality Monitoring: Implement validation checks and completeness controls to ensure accurate and consistent product data across channels.

Solution

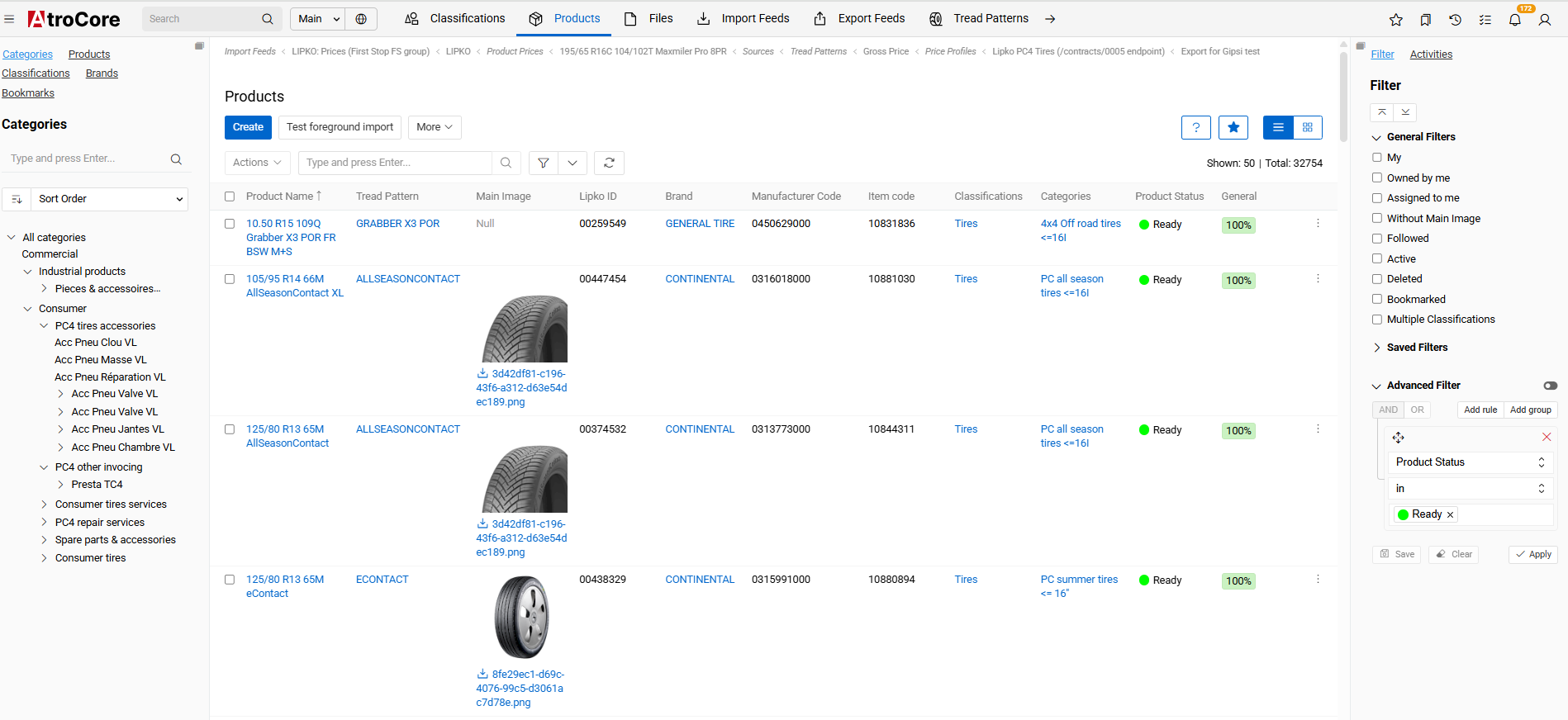

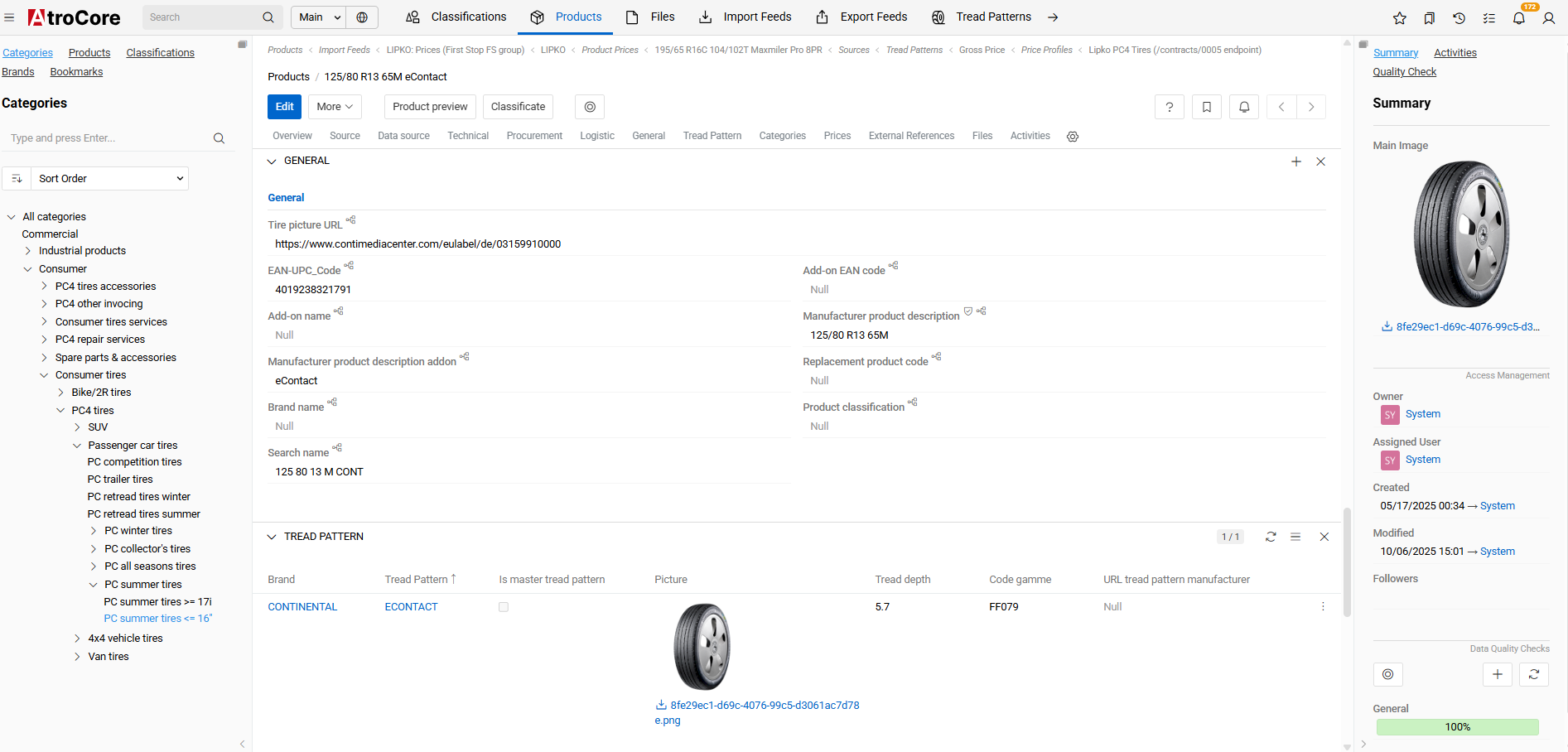

To achieve these goals, First Stop implemented a on-premise PIM soultion, AtroPIM system with robust data integration capabilities.

Key solution features included:

Flexible Data Model: A customizable data structure handles different data types, multilingual content, and team-specific layouts for logistics, marketing, and technical users.

Import and Export Automation: Automated feeds synchronize data from multiple sources and generate tailored exports for partners, including calculated attributes and channel-specific formats.

Dynamic Pricing Support: Pricing engine manages discounts and calculations based on product groups, user segments, and partner rules.

Data Quality Management: Validation tools check completeness and key attributes to ensure accurate and consistent product information at scale.

Dashboards and Reporting: Real-time dashboards track product status, completeness, and data quality across brands and categories.

Automated Workflows: Rule-based workflows handle product enrichment, categorization, status updates, and notifications, reducing manual work and errors.

Results

Better Catalog Management: The PIM made it easier to manage First Stop’s large product catalog, automate product creation, and reduce manual work.

Higher Data Accuracy: Validation rules, automated workflows, and completeness checks improved data quality and reduced errors.

Automated Data Updates: Imports and exports are now automated, keeping product information up-to-date across all channels.

Scalable Operations: Improved catalog and enrichment processes allow the team to handle more products efficiently and support business growth.

Faster Product Launches: Streamlined workflows enable quicker introduction of new products to market.

Better Collaboration: Centralized data allows marketing, logistics, and technical teams to work together more effectively.

Improved Reporting and Insights: Dashboards and analytics provide real-time visibility into product data quality, completeness, and catalog performance.