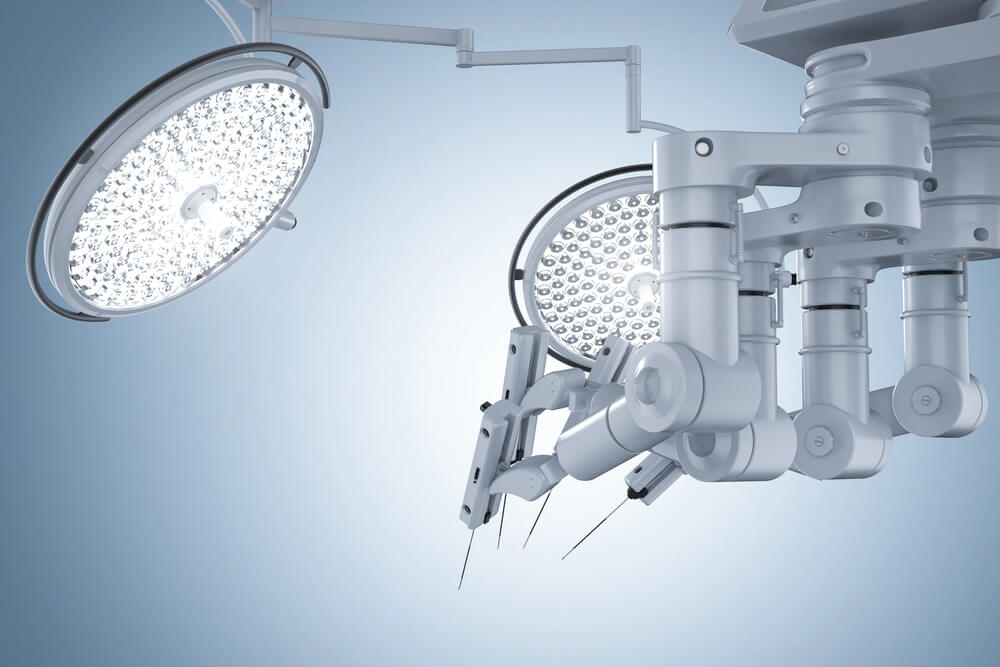

Derungs Licht is a Swiss lighting manufacturer based in Gossau, St. Gallen. The company develops and produces advanced lighting systems for hospitals, clinics, dental practices, and laboratories. With over 80 years of experience, Derungs is part of the Waldmann Group, an international network of lighting specialists.

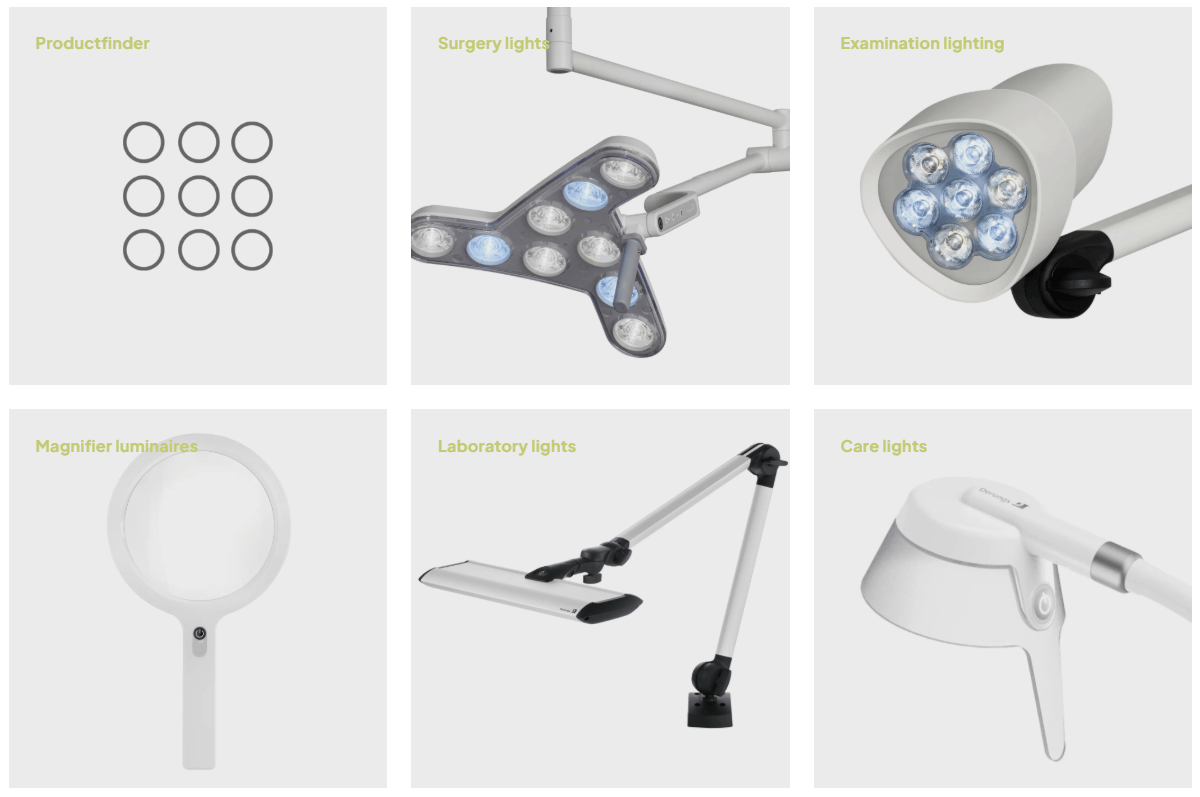

Its portfolio includes examination lights, ceiling systems, and task lighting, all designed for precision, hygiene, and visual comfort. Every product is developed and assembled in Switzerland under strict quality and regulatory standards.

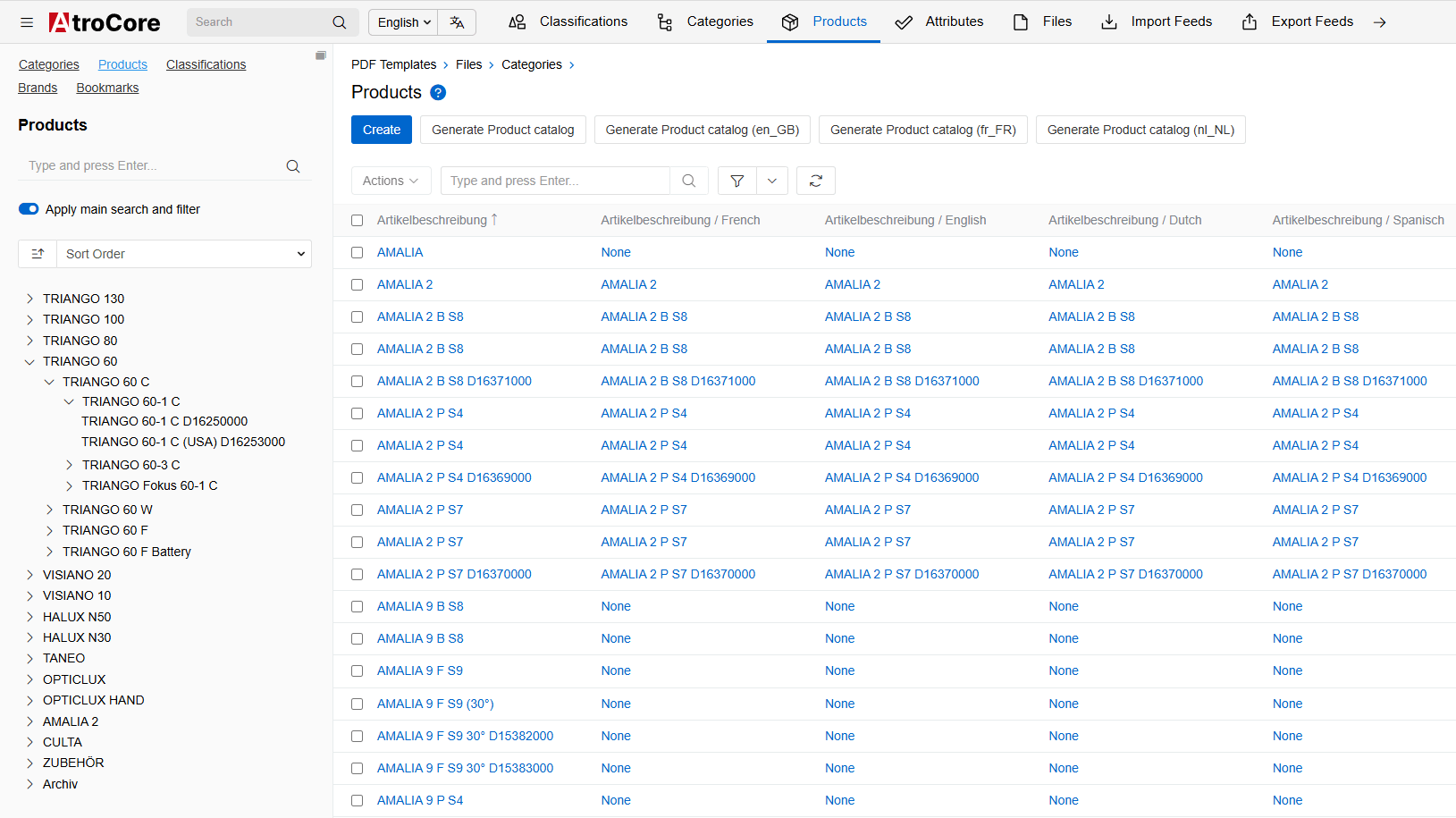

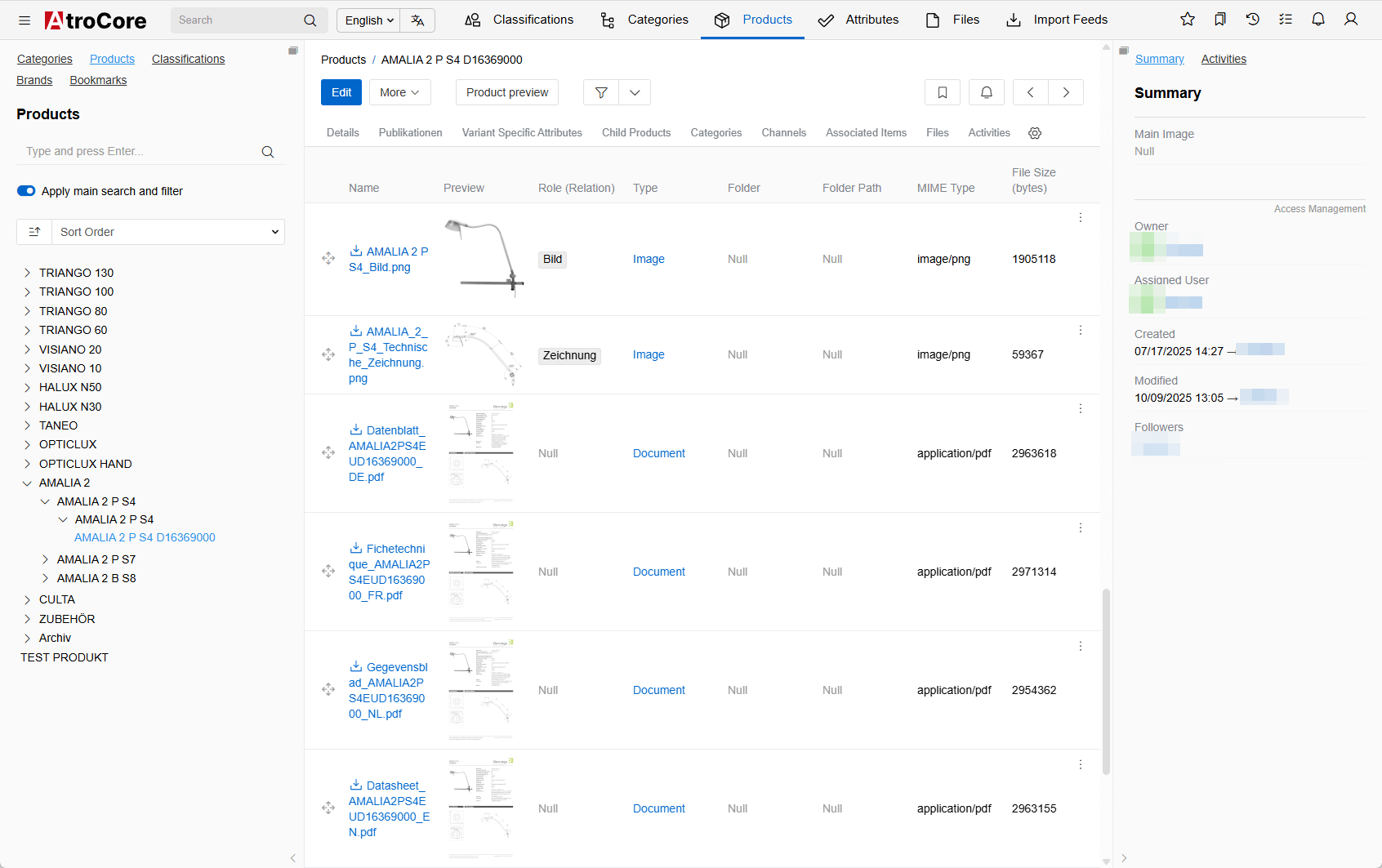

Derungs serves customers across Europe and worldwide through a network of distributors and partners, emphasizing reliability, compliance, and ergonomics. As a global supplier in a highly regulated industry, the company manages detailed product specifications, configurations, and certifications across multiple languages and regions. To handle this complexity efficiently, Derungs required a centralized system to control and publish product information across all digital and print channels.