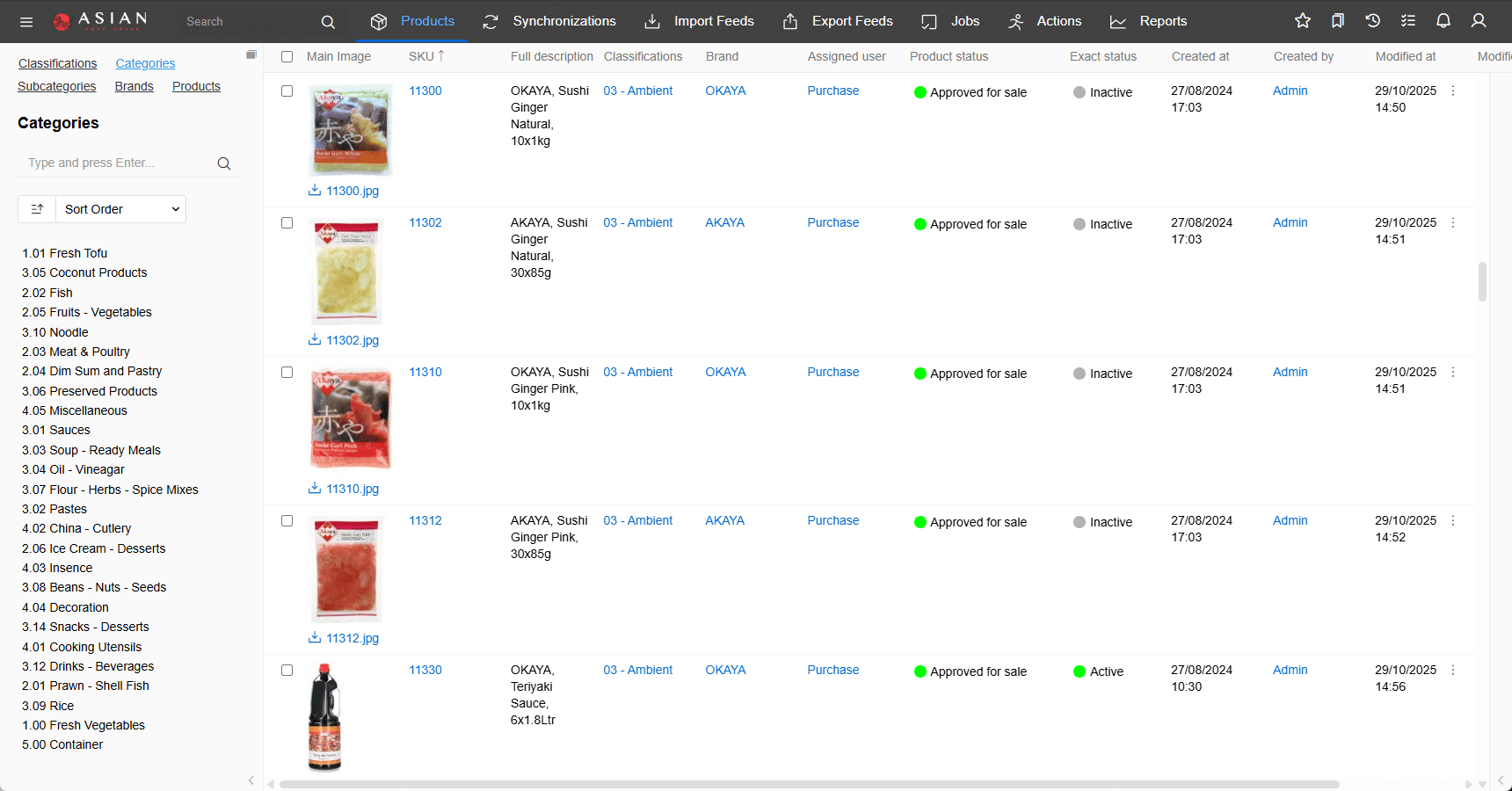

Asian Food Group is a leading European distributor of authentic Asian food and non-food products, offering an extensive range of over 3,500 items from more than 380 brands, including 14 exclusive and 11 own brands. Formed in 2022 through the merger of three family-owned companies (Lucullus, Thai Mas, and Sin Wah Foods), the group brings together over 80 years of experience in Asian food distribution.

Operating from a modern 30,000 m² BREEAM+ certified warehouse near the German border, Asian Food Group supplies customers in more than 35 countries across Europe. The company emphasizes efficiency, sustainability, and strong, long-term partnerships with both brands and retailers, while striving to make authentic Asian products easily accessible throughout Europe.