Adolf Nissen Elektrobau GmbH + Co. KG is a German manufacturer of mobile traffic management and road safety systems. The company was founded in 1914 and is headquartered in Tönning, Schleswig-Holstein. Nissen develops and produces LED variable message signs, mobile warning trailers, lamps, and intelligent traffic control systems for highways and work zones. It operates several branches across Europe, including Poland, Switzerland, Spain, and Austria. Nissen employs around 200 people and supplies public authorities, construction firms, and safety service providers. The company maintains ISO 9001, ISO 14001, and ISO 50001 certifications, ensuring high standards of quality, environmental responsibility, and energy efficiency.

Driving Digital Transformation Through Centralized Product Information

Challenges

Nissen faced several key challenges with its legacy Product Information Management (PIM) system:

Outdated PIM Infrastructure: Nissen’s old PIM system was slow, inflexible, and incompatible with new software and digital workflows.

Manual Multilingual Publishing: Creating localized, print-ready product data sheets required extensive manual effort and slowed documentation updates.

Fragmented Product Data: Information was scattered across systems, leading to inconsistencies in specifications, marketing texts, and compliance materials.

Complex Data Migration: Years of historical data, including drawings, compliance codes, and product configurations, had to be migrated without loss or corruption.

Inconsistent Data Quality: Manual inputs caused variations in product descriptions, specifications, and media assets.

Limited Integration Capabilities: The legacy PIM lacked modern APIs and connectors, making it difficult to synchronize data with ERP, CMS, and e-commerce platforms.

Goals

To modernize product data management and ensure accuracy across all channels, Nissen set out to:

Create a Central Source of Product Data: Implement a modern PIM platform to serve as the single source of truth for all product information.

Enable Automated Multilingual Publishing: Generate accurate, print-ready data sheets in multiple languages using automated templates.

Ensure Reliable Data Migration: Transfer all legacy and regulatory data to the new system with full validation and traceability.

Achieve Global Data Consistency: Apply strict data governance and validation to ensure uniform, compliant product content worldwide.

Improve Data Quality and Structure: Introduce standardized attributes, taxonomies, and controlled vocabularies to enhance data accuracy.

Prepare for Future Growth: Implement a flexible, scalable system to support Nissen’s expanding product portfolio and digital initiatives.

Solution

To meet Nissen’s strict requirements for data quality, consistency, and efficiency, a new Product Information Management (PIM) system was introduced as the central foundation for all product data.

Key solution elements include:

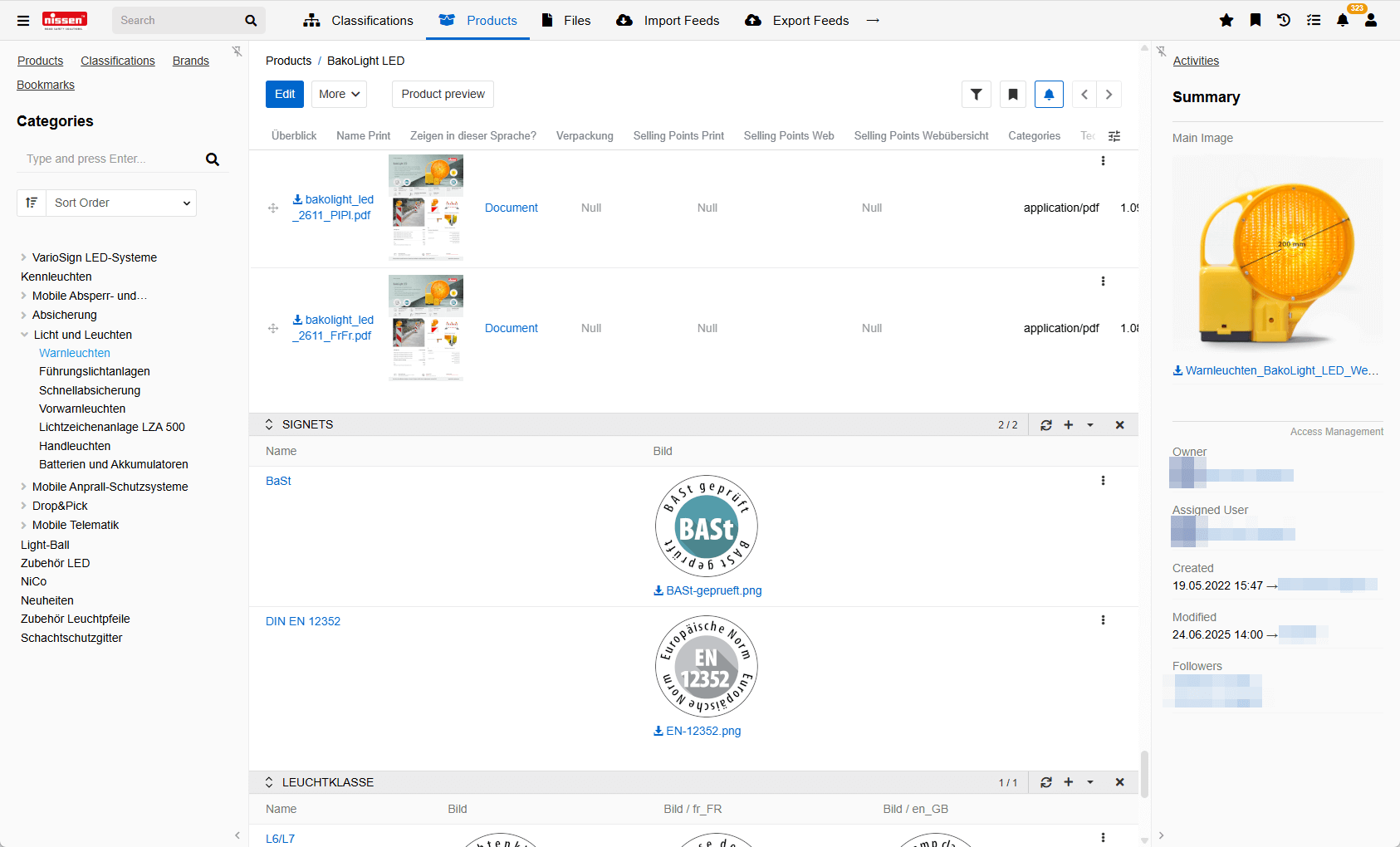

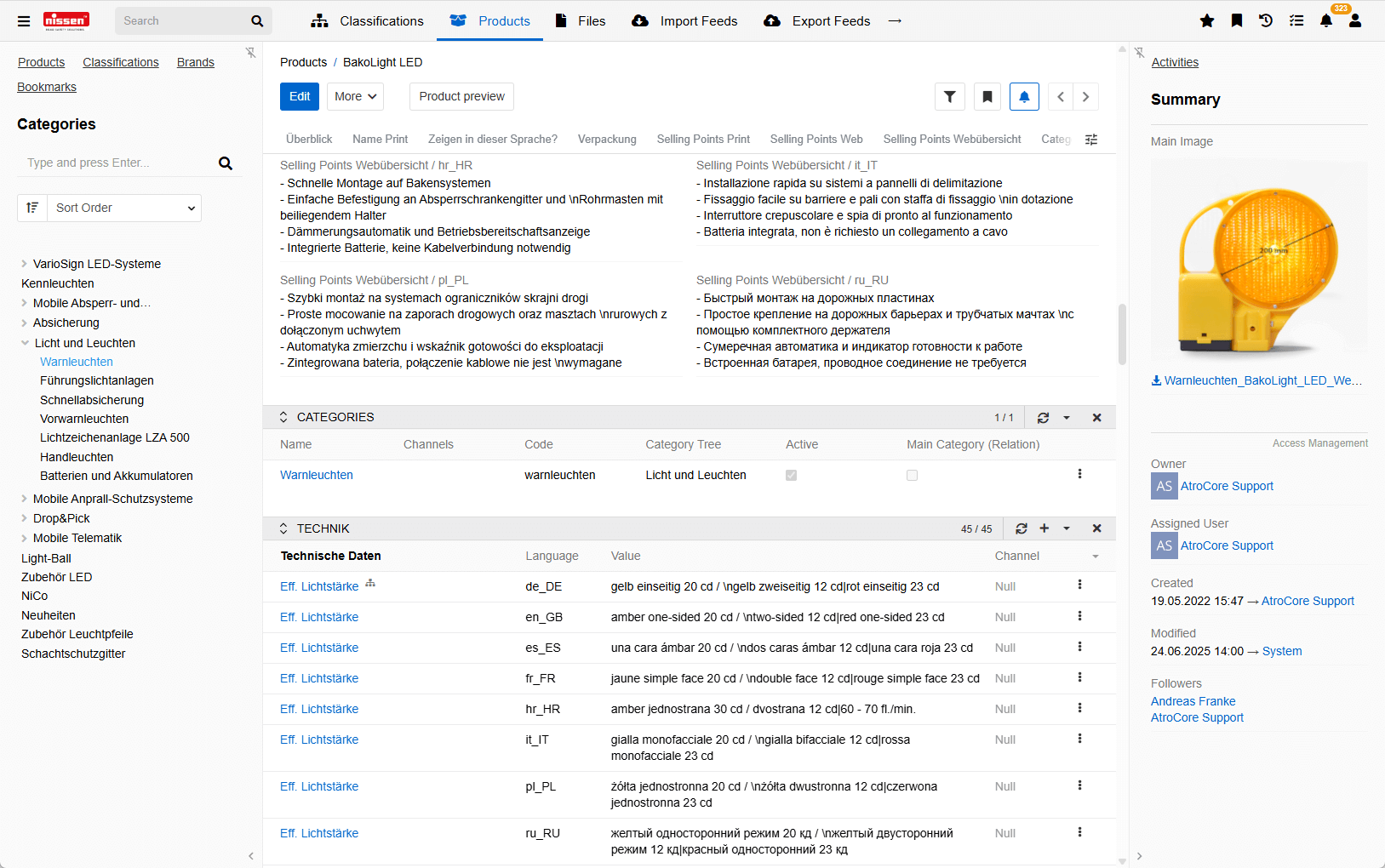

PIM Implementation and Central Repository: The new PIM became the single source of truth for all Nissen product data. A structured data model was developed to manage complex product hierarchies, safety requirements, and compliance attributes. R&D, Marketing, Sales, and Technical Documentation teams were trained to follow new governance and maintenance processes.

Flawless Data Migration: Product information from the legacy PIM and other databases was migrated to the new system. Millions of specifications, drawings, and compliance codes were verified through pre- and post-migration checks to ensure complete accuracy and data integrity.

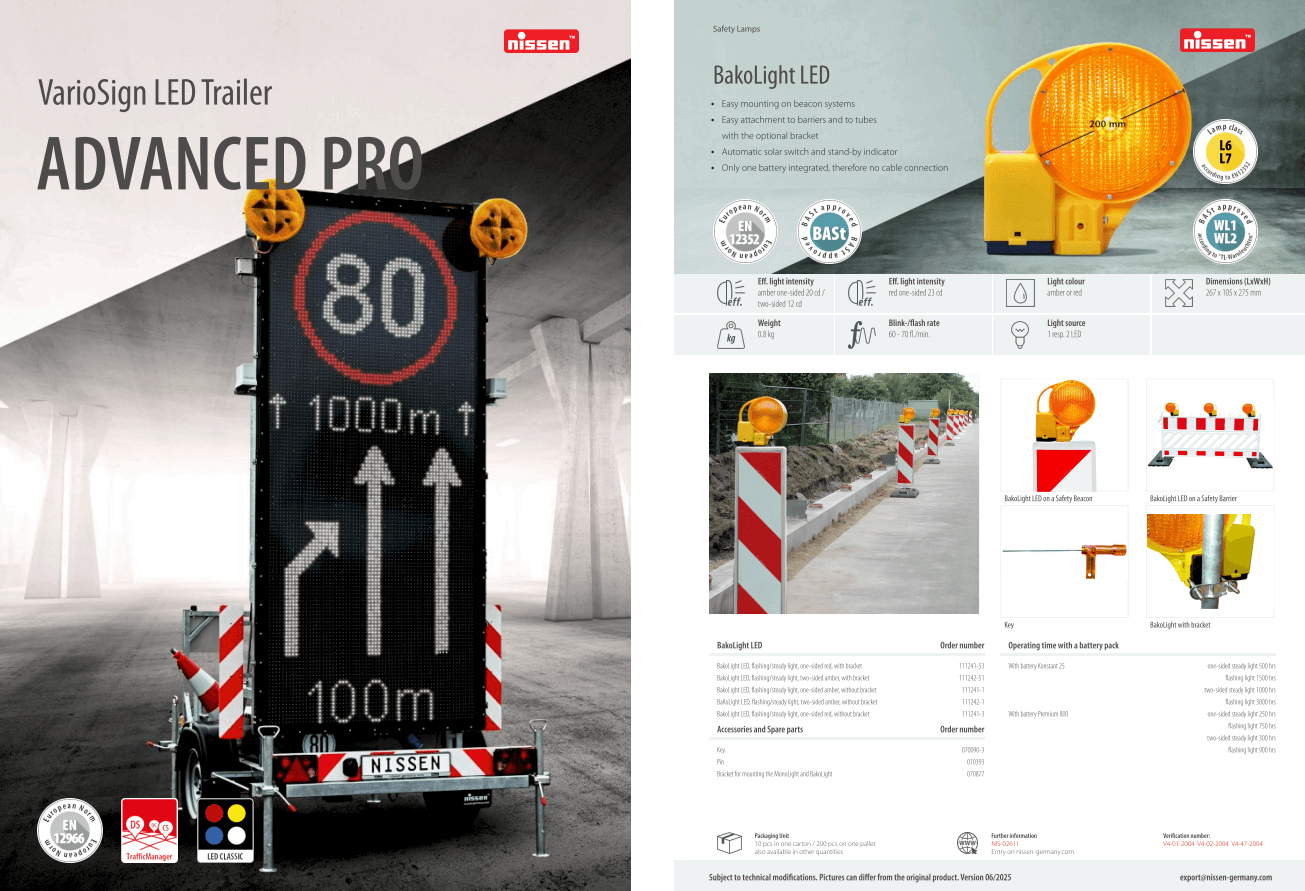

Automated Data Sheet Generation: The PIM now automates the creation of multilingual product data sheets. Configurable templates generate one- and two-page documents with consistent branding, pulling real-time data directly from the repository for international sales and marketing teams.

Improved Data Governance: Standardized workflows and validation rules ensure every product record meets internal quality and compliance standards. Automated checks and approval steps help maintain reliable, up-to-date product information across all channels.

Foundation for Future Scalability: The modular system architecture supports integration with ERP, e-commerce, and other digital platforms. It provides flexibility for future automation, new product lines, and multilingual publishing.

Results

Improved Data Quality: Nissen established a single, reliable source of product data. All channels now use consistent and compliant information without duplication.

Increased Efficiency: Automated template generation reduced the time needed to update specifications and documentation by more than 70%.

Faster Time-to-Market: Streamlined data entry and automated publishing allow new products to be launched significantly faster.

Enhanced Multilingual Publishing: Product sheets are now produced in multiple languages, supporting Nissen’s global sales and distribution network.

Higher Operational Productivity: Teams spend less time maintaining data and more time focusing on product development and innovation.

Scalable Digital Foundation: The AtroPIM-based system provides a flexible platform ready for future integrations, automation, and expansion.

Improved Cross-Team Collaboration: Centralized data access allows Marketing, Sales, and Technical teams to work from the same up-to-date information, reducing communication gaps and rework.